Ⅰ Configuration of main components

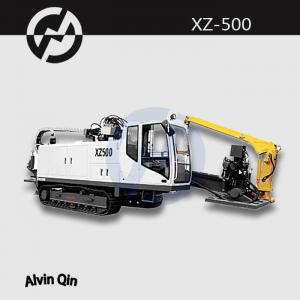

The XZ500 horizontal directional drilling rig is an integral device. The machine is mainly composed of the chassis, power unit, and drill stand, engine system, vice, cab, on-board crane, hydraulic system, electrical system and other components.

1. Chassis

The chassis is mainly composed of the main vehicle frame, left and right travel devices. The rear end of vehicle frame is fitted with hydraulic outriggers. The built-in planet speed reducer (with motor) is used as the travel speed reducer, which has a high output torque and a compact structure. The wired-controlled travel with two speeds adopted make it easy and safe to transfer and adjust the machine among work sites.

2. Engine system

The Cummins 194kW 6-cylinder water-cooled and turbocharged engine is selected. The max. pulling force is up to 500kN under the torque of 18000Nm.

3. Power unit

The power unit is driven by motor and speed reducer and its speed can be adjusted continuously so it is suitable for different work conditions. The power unit is fitted with damping device so that the drill stem threads are protected effectively.

4. Pusher and puller

The pusher and puller offers the feeding force or pulling force to the power unit through the motor, speed reducer and Rack-and-pinion. This mechanism is strong, reliable and stable. The drill stand is easy so slide back and forth to adapt to the drilling angle and gradeability.

5. Potent drill stem holder

It is composed of the upper and lower vices which operate in accordance with the rotation and movement of power unit to screw up or off the drill stem threads. Driven by the motor, the holder can move back and forth on the drill stand, and the distance between front and rear vices is adjustable.

6. On-board crane

The full-rotating telescopic-boom crane truck adopted facilitates the lifting, dismounting and mounting of drill stem and can also be used to lift other drill tools so as to reduce the work load.

7. Cab

The cab is an air-conditioned cab where the operator and direction controller can work together conformably.

8. Electrical system

It is mainly used to control the functions of rotation, pushing and pulling, vice and travel, etc, and to monitor the parameters and protect the engine and hydraulic system. It is composed of the left console, right console, instrument console and travel control box, etc.

9. Hydraulic system

The closed circuit control system is used as the power unit circuit, and the open circuit load sensing control system is used for drilling and pulling, which can save the energy effectively.

Ⅱ Optional parts for users

1. Drill stem and drill tool

The drill stem produced by Hebei Xuanhua, Wuxi Mineral Exploration Machinery or other producers can be selected. The cutting-type or squeezing-type expansion head with a diameter of 250mm~900mm can be selected.

2. Guide system

The wired or wireless direction control system can be selected.

3. Slurry mixing system

This system is composed of the engine, sewage pump, and slurry tank and swell soil mixer. The capacity of slurry tank can be 3m3 or 5m3 dependent on the user’s needs.